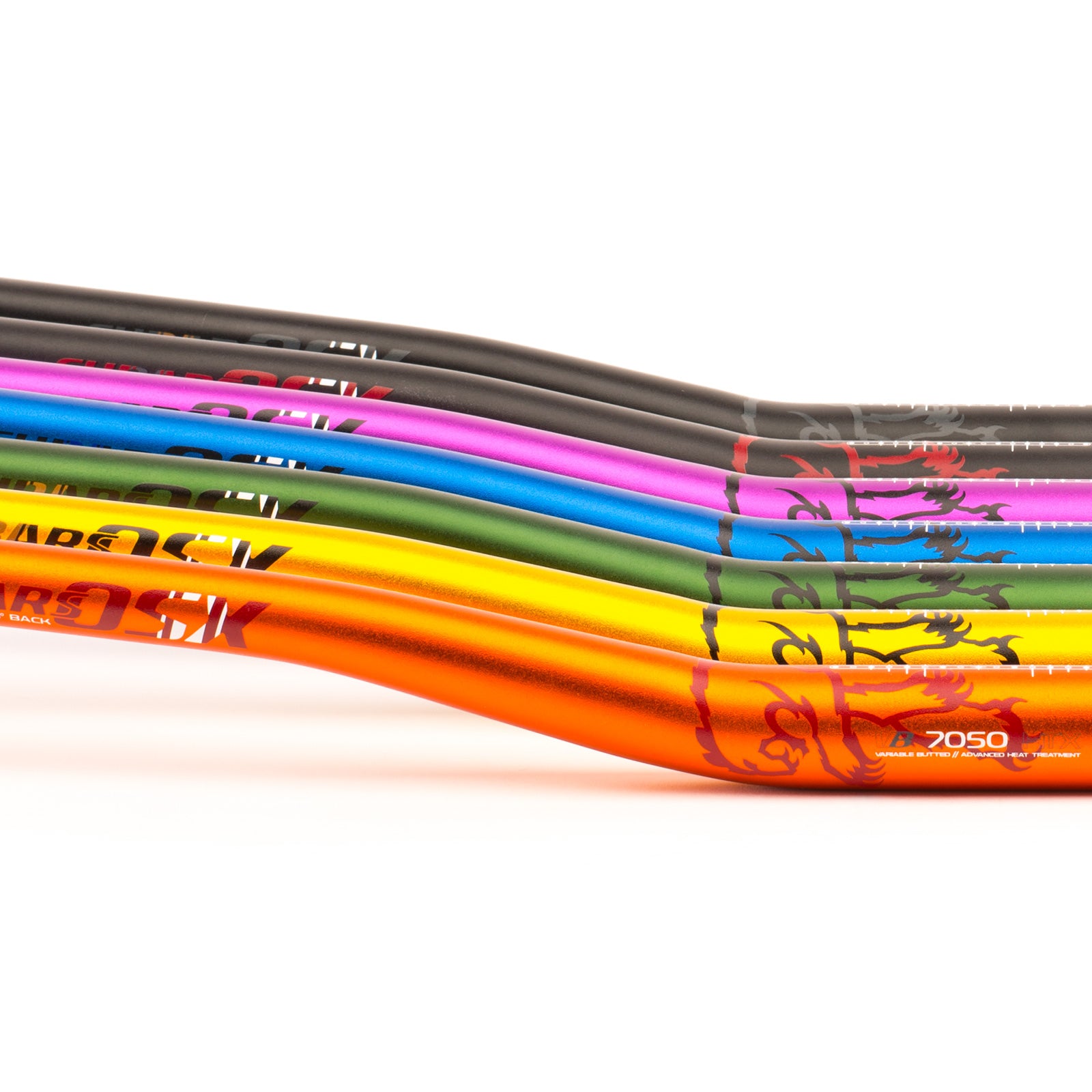

The benchmark in Alloy Handlebar Performance

OSX

Zedler Institut, Germany

Zedler is known within the cycling industry as the foremost test institute for bicycle frames and components. Based in Germany, they have been making test equipment and conducting third party testing for 30 years. In the cycling industry, the most common testing standard for bicycles and components, the EN/ISO Standard, is decades old and not really relatable to the kind of loads that modern components see. For this reason, Zedler have created test standards that test up to the EN/ISO standard and then far beyond this, to simulate the most extreme scenarios that today’s components will see in use.

Testing

Part of the latest evolution of our handlebars was to ensure that all of the design improvements we’ve made translated in to real-world, measurable increases in performance. Part of this was to build our own test lab and equipment, where we can test prototype and also production batches of handlebars for safety and performance. We also sent our new carbon bars to Zedler to test them to their high industry standard, which allows us to benchmark them against other products available on the market.

The tests in question relate to the fatigue life of the bar, and are designed to simulate the loads that the handlebar will see over its entire service life. These include a precisely designed and controlled sequence of loads on the handlebar in all directions, and also a ‘Push-Pull Test’ which as the name suggests, pushes and pulls on the bars with a high force, in the middle of the test. In the real world, this could relate to landing a large drop to flat after already riding the bar for a few years.

Both the Cutlass and BZA passed the highest test standard available from Zedler, the ‘Advanced Plus’ test. Both handlebars were intact at the end of these tests, and we stopped ‘End of Life’ testing when it became clear that it may take many more rounds of testing to see a failures from the bars.

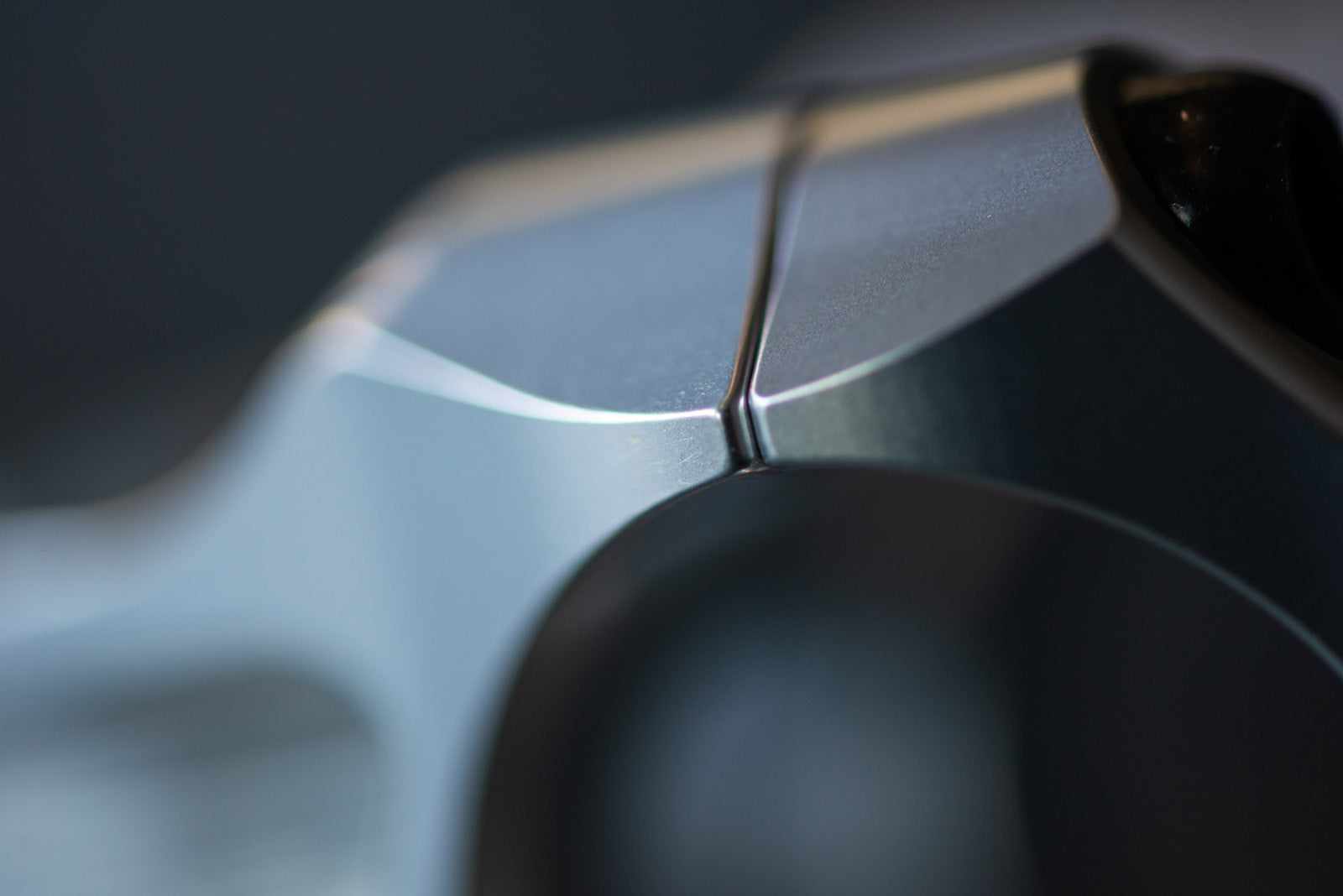

key features

More than meets the eye, our bars are a carefully tuned piece of kit.

Bar FAQ's

Nowadays there are really only two bar clamp diameters, 31.8mm and 35mm. You should check your stem to see what you currently have.

If you are buying a new stem, be sure to match up the clamp size.

There is no real lifespan to our alloy bars, however if you've had a big crash it's probably a good idea to change your bar.

You should frequently inspect your bars for bends or signs of damage.

You absolutely can (and likely should) cut your bars down! They will still be covered under our warranty and crash replacement programs.

Remember to cut them down evenly on both sides.

This is the source of great debate. We can't really offer an exact rule other than to try and test what others have, and don't be hasty to cut too much off.

In short, start small!

Technically our carbon bars produce stronger test results, however they are more likely to pickup damage in a crash.

If you are the sort of person who doesn't like inspecting their bike after a crash and changing out parts as a precautionary measure, we recommend going with alloy.

You can read the full user guide here, but mainly make sure the clamping surfaces are clean, the stem faceplate is installed evenly (top to bottom), and always follow the torque specifications for the stem, grips and controls.

As a general rule, you should be able to move your controls by hand, after tightening.